Got Wonky Walls?

Most homes are a little (or a lot) out of square on the inside walls. What this means is that if you put a perfect square into a corner, like the corner where a countertop goes, it’s not going to fit perfectly.

Maybe there is a little gap at the back or the side. Or, worse, at the back AND at the side.

Getting Granite Counters to Fit Right

Making counters that fit means first making a pattern. If the pattern fits, and the granite is cut with the pattern, then the finished counters will fit where they are supposed to.

We call these patterns granite templates.

Sometimes we need them, sometimes we don’t. When we come out to measure for your countertop job, we’ll see how square (or out of square) the walls are and then make the templates that we need.

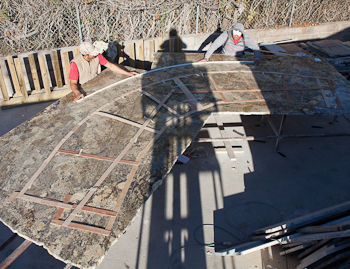

Making a Granite Template the Old Fashioned Way

We’ve heard that there are snazzy ways to make templates.

We do ours the old fashioned way: by hand.

We do them this way because it works. It gives us a chance to understand the lay of the land, so to speak. It also gives us a few extra minutes to chat with our customers, to listen to what they really want out of their countertop job.

Later, when we’re laying out the counters, we can use the templates to make sure that the most attractive parts of the granite ends up on the finished counters. They help us spot areas that would look better if the templates were moved a little bit to capture something special in the stone on prime countertop areas.

This is all the more important when the counters will be made from a stone that has lots of movement – areas where the coloration changes over large areas, sometimes in big sweeping swirls or lines.

Oh Yes! The Counters Fit!

We love it when our clients are happy with the finished job. One thing they often mention is how well the countertops fit, even in an old house with uneven walls. Making them to fit makes the whole job easier on everyone, and makes the installation go much smoother.

One extra note – the templates in the top two photos got done twice. One set for us to cut the job, and another set that went to a custom iron guy – Lee with Heart of Texas Metalworks. Lee is making a “torsion box”, a rigid metal frame to go under the countertop to provide the necessary support across the front of the counter. Without that frame, the front edge of the counter would have had too long of a span, and would most likely break when my sons jump up on the front edge to get to stuff in the cabinets above the washer and dryer. (No, they shouldn’t jump up there, but they most certainly will!)

Hopefully, we’ll get some photos up in a few weeks with the counters, and you can see the job from templating-to-installation. Maybe that can help you plan for your own countertop project!

Leave a Reply